- Home

- Profile

- News

- Products

- Industries

- Suppliers

- Help

- Contact

MCM Moisture Analysers (Hygrometers)

Moisture Control & Measurement Ltd (MCM) are the globally recognised leaders in gas moisture analysis. MCM are proud to manufacture and supply trace moisture analysers that are the preferred choice of industry experts for a wide variety of applications around the world.

With over 40 years of experience in hygrometry, MCM stand at the forefront of our chosen industry.

MCM was established in 1968 with the primary goal of developing moisture standards for the UK defence industry. Subsequently, by the mid 1970s, it became clear that the moisture analysers (hygrometers) available at that time could no longer match the performance of our new moisture generators and calibrators. And so a fresh R&D agenda was devised. With a drive for progression MCM began work on improving sensing techniques, looking for an alternative to the traditional measuring devices.

If it's true that good things come to those who wait, then the patience of the MCM team was rewarded with the development of the Silicon Chip Sensor. Unique in the field of moisture measurement, this revolutionary Sensor was pioneered in the early 1980s and its superior performance would be synonymously linked with MCM’s commitment to quality and original design. The Silicon Chip allowed MCM to push the boundaries of performance, offering the user unique features such as Temperature Control and the Push Purge® Sensor heating feature, which helped provide the fastest, most stable and most repeatable moisture analysers on the market.

Today, more than 25 years after the Silicon Chip was pioneered, MCM are still the only manufacturer to use this technology, and the associated advantages and benefits of its use remain unique to our instrumentation. With the principle of operation well established, we’ve developed new moisture analysers (hygrometers) that are geared towards ease of use and quality data capture, for rapid and reliable hygrometry applicationsthroughout the world.

Rapid response

Watch how quick MCM's unique silicon sensor performs from wet to dry and back again. Dry down to 2 ppmV in less that 2 1/2 minutes!

![]()

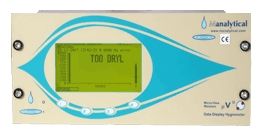

MicroView

MicroView

Moisture in gas analyser

The MicroView and On-Line Hygrometer can sample inert and non-reactive gases. It is ideal for applications where fast speed of response and reliable data collection are important, and the ability to provide audit records is of benefit.

- Temperature Controlled Silicon Sensor transfers laboratory accuracy in to the field, offering a Transfer Standard instrument with unrivaled speed of response.

- Automatic Push Purge® Sensor dry down for rapid response and elimination of hysteresis.

- Graphical display for detailed sample information and audit capability.

- Internal data log feature stores measurements in the instrument memory for review at a later time.

![]()

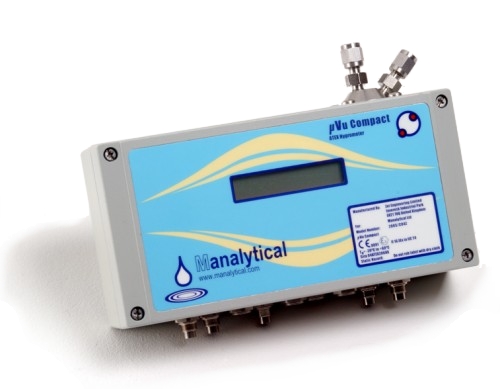

MicroView Mini

MicroView Mini

Moisture in gas analyser

The brand new MicroView Mini Hygrometer combines MCM's key performance advantages in an unbeatable entry-level transmitter.

The MicroView Mini is ideal as a stand-alone transmitter, or as the keystone of a more complex system solution.

- Temperature Controlled Silicon Sensor transfers laboratory accuracy in to the field, offering a Transfer Standard instrument with unrivaled speed of response.

- Automatic and manual Push Purge® Sensor dry down for rapid response and elimination of hysteresis.

- Local display and 4-20 mA output

- Highly accurate with a 0.1 ppm[V] resolution over a range of 0 to 100 ppm[V]

- Full scale wet to dry in under 1 minute!

![]()

MicroView Mini - Ex d (IECEx certificate)

MicroView Mini - Ex d (IECEx certificate)

Moisture in gas analyser

Ideally suited to any hazardous area process application that requires precise moisture control in the sub parts per million [ppmV]

range, not only does the MicroView Mini Hygrometer Ex-d deliver cutting edge analysis, it is also a dream for the process engineer

and instrument technician. Ready to install direct from the box, the analyser has no complex setup, commissioning or operational

requirements and is completely “self-managing” in all aspects of routine use. Compared to alternative hygrometers that require

detailed programming of instrument parameters, precise control of sample conditions and inefficient maintenance interventions,

the MicroView Mini Hygrometer Ex-d is the very definition of a “plug and play” analyser solution.

- Temperature Controlled Silicon Sensor transfers laboratory accuracy in to the field, offering a Transfer Standard instrument with unrivaled speed of response.

- Local display and 4-20 mA output

- Fast and Simple installation - No hidden buying costs, analyser ready out of the box.

- Highly accurate with a 0.1 ppm[V] resolution over a range of 0 to 100 ppm[V]

- Full scale wet to dry in under 1 minute.

- Ideal for Hydrogen, LNG, Natural gas, and industrial gases

![]()

MicroView Mini Trace 3 - (0.1 to 1000 ppb measurement)

MicroView Mini Trace 3 - (0.1 to 1000 ppb measurement)

Moisture in gas analyser

0.1-1000 ppbV range, resolution of 0.2 ppbV and unrivalled response to moisture excursions, the MicroView Mini Trace-3 Hygrometer provides a level of detail that puts you in charge of your process. In short, it provides real-time data and a level of accuracy unattained by any other technology.

- Small footprint aids project design

- Fast and Simple installation - No hidden buying costs, analyser ready out of the box.

- Highly accurate with a 0.2 ppb[V] resolution over a range of 0.1 to 1000 ppb[V]

- Provides proven and robust operation “in the field”

- Long mean service interval

- ISO 17025 calibration option for maximum traceability

![]()

MicroView ATEX (IECEx conformity available!)

MicroView ATEX (IECEx conformity available!)

Moisture in gas analyser

- MCM’s hazardous on-line hygrometer redefines hazardous area applications.

- Ex ia IIC T4 Ta = -20ºC to +60ºC.

- Suitable for use with inert and hazardous gases including Natural Gas, methane, LNG / LPG, H2, and volatile hydrocarbons (up to C5).

- Used as the base component for Self-Validating and Self-Calibrating Systems – ideal for demanding gas applications.

![]()

MicroView Portable

Moisture in gas analyser

The MicroView Portable Hygrometer can sample inert and non-reactive gases. This portable meter is ideal for applications where fast speed of response and reliable data collection are important, and the ability to provide audit records is of benefit.

- Temperature Controlled Silicon Sensor transfers laboratory accuracy in to the field, offering a transfer standard instrument with unrivaled speed of response.

- Automatic Push Purge® Sensor dry down for rapid response, elimination of hysteresis and resistance to contamination.

- Graphical display for detailed sample information and audit capability.

- Internal data log feature stores measurements in the instrument memory for review at a later time.

- Ex ia IIC certified model available with IECEx conformity

![]()

Self-Validating Systems

Self-Validating Systems

Moisture in gas analyser

The MCM ATEX Auto-Zero System provides high precision, on-line moisture analysis in applications where levels of contamination are greater than normal and routine servicing is impractical.

- A cost-effective methodology to help mitigate the effects of contamination.

- Reduces the necessity for operator interface and maintenance

- 24 hour uninterrupted operation.

- Extends the mean service interval of the System and reduces maintenance costs.

- Ideal for Natural Gas and Petrochemical applications. For example: Offshore Platforms, FPSOs, Post-Glycol 'Contactor' Monitoring, LNG, Pipeline Drying, Natural Gas Storage & Distribution, Receiving Terminals (Custody Transfer) and LPG Container Transfer.

- Customised Auto-Zero & Span Systems are also available.

![]()

Self-Calibrating System

Self-Calibrating System

Moisture in gas analyser

Developed for catalytic reforming applications in the refinery industry, our most comprehensive analyser system comprises dual sensors and an internal, prime-standard moisture generator.

The MCM Continuous Moisture Measuring System (CMMS) provides catalytic reforming applications with the most accurate and reliable means available for on-line monitoring of moisture in recycle gas. Utilising our unique Temperature Controlled Silicon Sensor, the CMMS detects changes as low as 1 ppm[V] and stands up to corrosives, such as chloride, ensuring representative sampling of the recycle gas stream.

MCM’s Temperature Controlled Silicon Sensor brings distinct benefits to catalytic reforming applications:

- Silicon sensors have unique moisture capacitance behavior, enabling accurate measurement of moisture measurement in recycle gas in the range 0 to 800 ppm[V].

- The Silicon sensor is unaffected by chloride levels up to 150 ppm[V].

- Silicon sensors can resist corrosive agents, such as HCl, that are commonly found in recycle gas. As a direct result, sensor life is measured in years, rather than months.

- The unrivaled speed of response of a Silicon sensor means that, upon commissioning or after exposure to high moisture levels, the system requires only a short period of dry down to provide accurate data.

- Automatic recalibration is accomplished daily, using three internally generated, prime moisture calibration standards. By using a newly calibrated Sensor every 24 hours, the MCM CMMS eliminates the potential for long-term drift and offers extreme accuracy, stability and repeatability